A Comprehensive Guide to Popular Cabinet Materials

A Comprehensive Guide to Popular Cabinet Materials

When selecting panel materials and finishes, it's crucial to consider the specific requirements and intended use, as each option has its own advantages and limitations. Keep reading and get to figure out more about popular materials for cabinets.

I. Substrate Materials for Panels

1. Solid Wood Panels

The substrate for solid wood panels is made entirely from natural wood. It is finished with wood wax oil or paint, offering a natural wood grain texture. Solid wood exhibits remarkable malleability, environmental friendliness, and the ability to accommodate various designs, making it a suitable choice for wardrobe panels. Solid wood panels are not only environmentally friendly and health-conscious but also possess a sophisticated texture and versatile design options.

2. Particleboard Panels

Particleboard is composed of wood chips bonded together with adhesive, making it a common choice for cabinet doors across many brands. It offers a variety of surface finishes. However, particleboard doors may deform when used for taller cabinets, except for some imported brands of particleboard. These panels are best suited for a minimalist style as they are not conducive to intricate designs.

3. MDF (Medium Density Fiberboard) Panels

MDF panels are made from wood fibers, often requiring more adhesive. If the density is insufficient, these panels may lose their moisture resistance and become prone to swelling. In regions with higher humidity, such as areas with heavy rainfall or lower floors, MDF is not recommended.

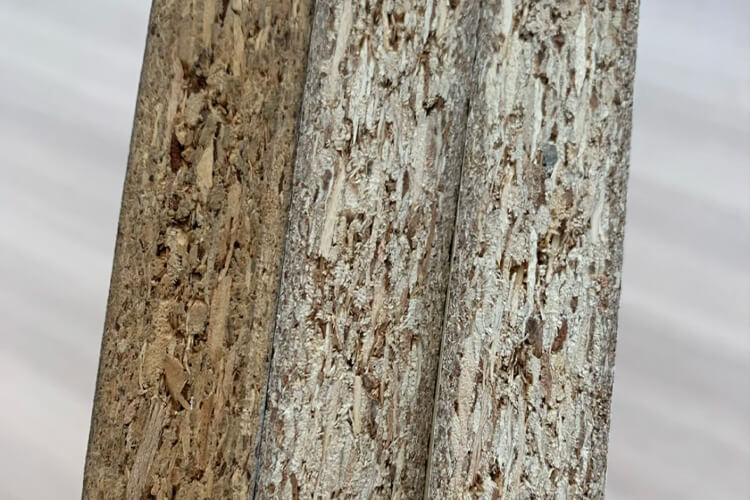

4. OSB (Oriented Strand Board) Panels

The production process of OSB panels is similar to that of particleboard. However, OSB panels have larger wood chip fragments, arranged in a crisscross pattern, providing excellent durability and nail-holding strength. Nevertheless, they are not ideal for highly intricate cabinet designs.

5. Glass Panels

Common glass panel options include ultra-clear glass, colored glass (gray, tea-colored), tempered glass, and frosted glass. When customizing, using glass panels in specific areas can enhance transparency and design aesthetics. The addition of internal LED lighting can greatly improve the visual appeal of the space.

II. Surface Finishes

1. Lacquer Painted Panels

Lacquer painted panels are created by applying paint to the surface after meticulous sanding and subjecting it to high-temperature curing. These panels boast a vibrant and long-lasting color, and they resist fading. Due to the paint application, they do not require edge banding, which enhances their waterproof properties. It is advisable to use particleboard or solid wood as the base for lacquer panels; choosing a matte finish enhances the texture.

2. Melamine Panels

Melamine surface panels, also known as dual-surface panels, involve soaking paper with different colors or textures in melamine resin adhesive. This treated paper is then applied to the surface of particleboard or MDF and pressed together through heat and pressure. They offer a wide range of patterns, rich textures, and high fidelity to wood grains. These panels are highly resistant to wear and acid-alkali corrosion, but they may have subpar moisture resistance.

3. PET (Polyethylene Terephthalate) Panels

PET panels are usually constructed on a base of medium-density fiberboard and can be made with a high-gloss or matte (textured) finish. Additionally, PET films have the hardness necessary to provide excellent protection for the panels, making them highly wear-resistant and moisture-resistant. They are well-suited for cabinet use. PET panels offer high wear resistance, moisture resistance, and a smooth touch, although they tend to be more expensive and are best suited for flat surfaces without intricate designs.

4. Vacuum-Formed Panels

Vacuum-formed panels, also known as thermoformed panels, primarily use medium-density fiberboard as the base material. The material is milled and polished before a PVC surface is tightly adhered using vacuum pressure. These panels offer a wide range of colors and designs but may have lower environmental friendliness. They are known for their rich colors and designs but may lack in environmental considerations.